Makesse Makine

Makesse Makine draws its strength from the fact that its engineer-based founding partners have brought together 10 years of industry experience in the fields of automotive, machinery manufacturing and quality management systems. With its innovative, agile and professional approaches, it continues to make a difference from its competitors in the machining sector.

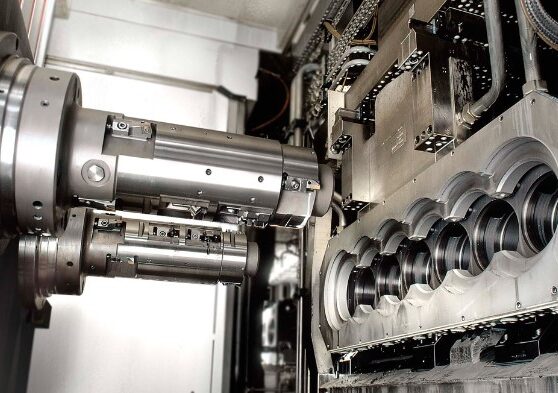

Makesse Makine; is a business partner for the spare parts needs of all processes of industries such as automotive, machinery, energy and textile. Stainless, titanium, metal, brass, engineering plastics etc. It processes metal or non-metal raw materials with high precision CNC machines and produces parts that require special design. By applying the requirements of the Quality Management System throughout all production processes, meeting customer expectations on time; manufactures high-quality, high-precision products.

Makesse Makine continues its design and R&D activities with its own resources; By contributing to the design and R&D studies of its customers, it makes the first prototype production and then mass production.

There’s no simple way to describe the benefits of high-quality, precision machining and its importance in today’s economy!

Industries that benefit from metalworking and machining include automotive, aerospace, agriculture, construction, power generation, marine, transportation and more. Makesse Makine is the professional business partner of all industries with its machine park with different features.